Why Architects should consider the use of steam energy on their next building

07/19

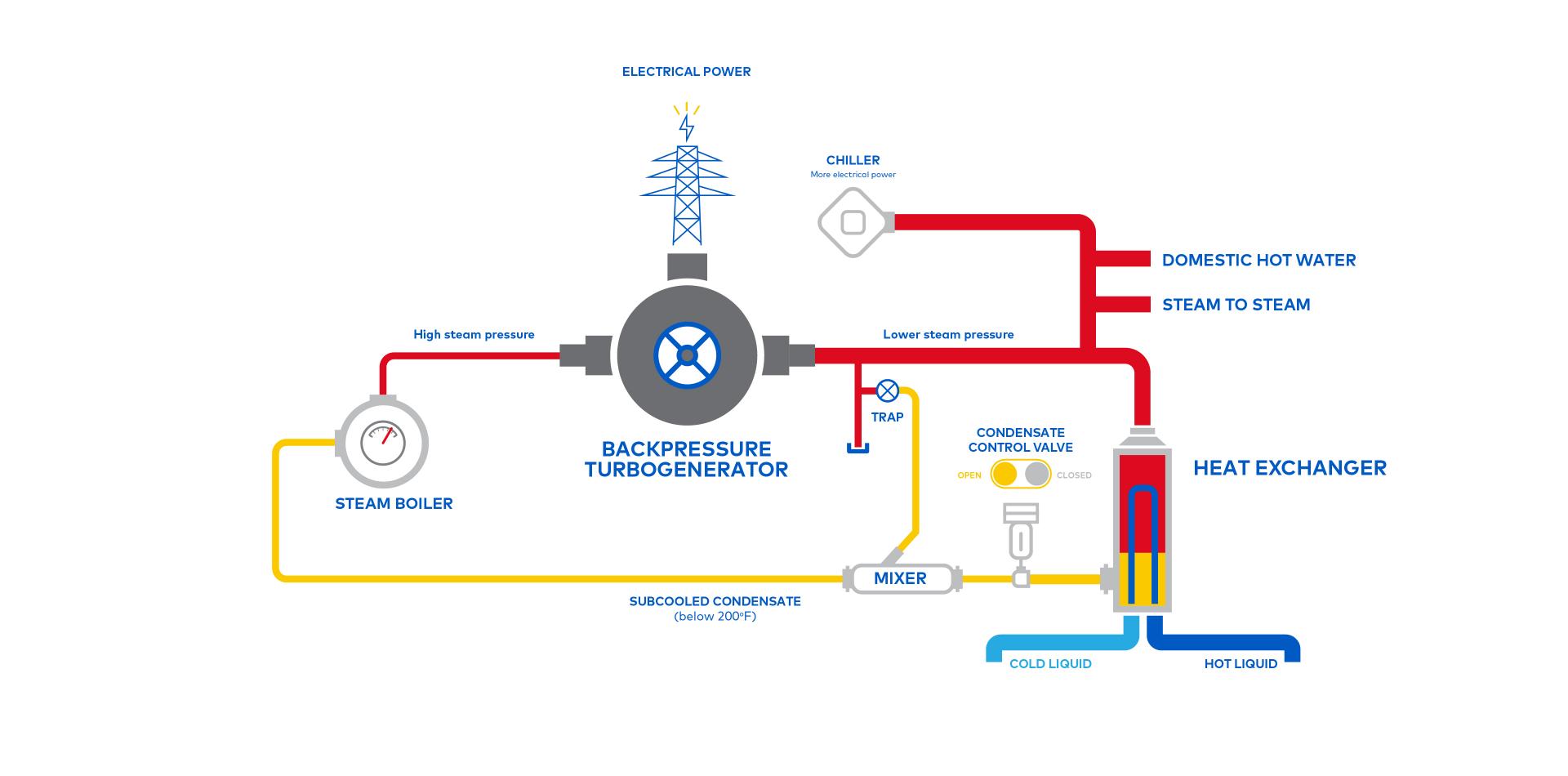

Many industrial facilities produce steam at a pressure higher than that demanded by process requirements. Steam passes through pressure-reducing valves (PRVs, also known as letdown valves) at various locations in the steam distribution system to let down or reduce its pressure. A noncondensing or backpressure steam turbine can perform the same pressure-reducing function as a PRV while converting steam energy into electrical energy.

In a backpressure steam turbogenerator, shaft power is produced when a nozzle directs jets of high-pressure steam against the blades of the turbine’s rotor. The rotor is attached to a shaft that is coupled to an electrical generator. The steam turbine does not consume steam. It simply reduces the pressure of the steam that is subsequently exhausted into the process header.

Cost-Effective Power Generation

In a conventional, power-only steam turbine installation, designers increase efficiency by maximizing the pressure drop across the turbine. Modern Rankine-cycle power plants with 1,800-pounds-per-square-inch-gauge (psig) superheated steam boilers and condensing turbines exhausting at near-vacuum pressures can generate electricity with efficiencies of approximately 40%.

Most steam users do not have the benefit of ultra-high-pressure boilers and cannot achieve such high levels of generation efficiency. However, by replacing a PRV with a backpressure steam turbine, where the exhaust steam is provided to a plant process, energy in the inlet steam can be effectively removed and converted into electricity. This means the exhaust steam has a lower temperature than it would have had if its pressure had been reduced through a PRV. In order to make up for this heat loss, steam plants with backpressure turbine installations increase their boiler steam throughput.

Thermodynamically, the steam turbine still behaves the same way that it would in a conventional Rankine-cycle power plant, achieving isentropic efficiencies of 20% to 70%. Economically, however, the turbine generates power at the efficiency of your particular steam boiler (modern steam boilers operate at approximately 80% efficiency), which then must be replaced with equivalent kilowatt-hours (kWh) of heat for downstream purposes. The resulting power generation efficiencies are well in excess of the average U.S. electricity grid generating efficiency of 33%. Greater efficiency means less fuel consumption; backpressure turbines can produce power at costs that are often less than $0.04/kWh.

Backpressure Turbogenerator Applicability

Packaged or “off-the-shelf” backpressure turbogenerators are now available in ratings as low as 50 kW. Backpressure turbogenerators should be considered when a PRV has constant steam flows of at least 3,000 pounds per hour (lb/hr), and when the steam pressure drop is at least 100 psi. The backpressure turbine is generally installed in parallel with the PRV.

Estimating Your Savings

To make a preliminary estimate of the cost of producing electrical energy from a backpressure steam turbine, divide your boiler fuel cost in dollars per million Btu ($8.00/MMBtu) by the product of your boiler efficiency (Eb, 80%) and electrical generator efficiency (Eg, 95%). Then convert the resulting number into cost per kWh, as shown in the sample calculation below:

- Electricity Cost = Fuel Cost ($/MMBtu) x 0.003412 MMBtu/kWh/(Eb x Eg)

- Example: ($8.00/MMBtu x 0.003412 MMBtu/kWh)/(0.80 x 0.95) = $0.036/kWh

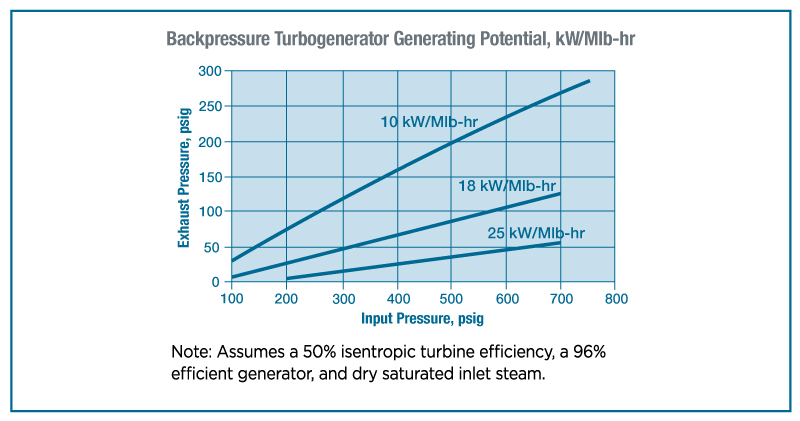

To estimate the potential power output at a PRV, refer to the figure below, which shows lines of constant power output, expressed in kW of electrical output per 1,000 pounds per hour (Mlb-hr) of steam throughput, as a function of turbine inlet and exhaust pressures. Look up your input and output pressure on the horizontal and vertical axes, and then use the reference lines to estimate the backpressure turbogenerator power output per Mlb-hr of steam flow. Then estimate the total installed generating capacity (kW) by multiplying this number by your known steam flow rate. The annual cost savings from the backpressure turbine can then be estimated as:

- Power Output (kW) x Steam Duty (hr/yr) x (Cost of Grid Power – Cost of Generated Power, $/kWh)

Life and Cost of Backpressure Turbogenerators

Turbogenerators with electrical switchgear cost about $900/kW for a 150 kW system to less than $200/kW for a 2,000 kW system. Installation costs vary, but typically average 75% of equipment costs.

Backpressure steam turbines are designed for a 20-year minimum service life and are known for having low maintenance requirements.

Suggested Actions

Consider installing backpressure turbogenerators in parallel with PRVs when purchasing new boilers or if your boiler operates at a pressure of 150 psig or greater.

- Develop a current steam balance and actual process pressure requirements for your plant.

- Develop steam flow/duration curves for each PRV station.

- Determine plant electricity, fuel cost, and operating voltage.

- Consider either one centralized turbogenerator or multiple turbogenerators at PRV stations.